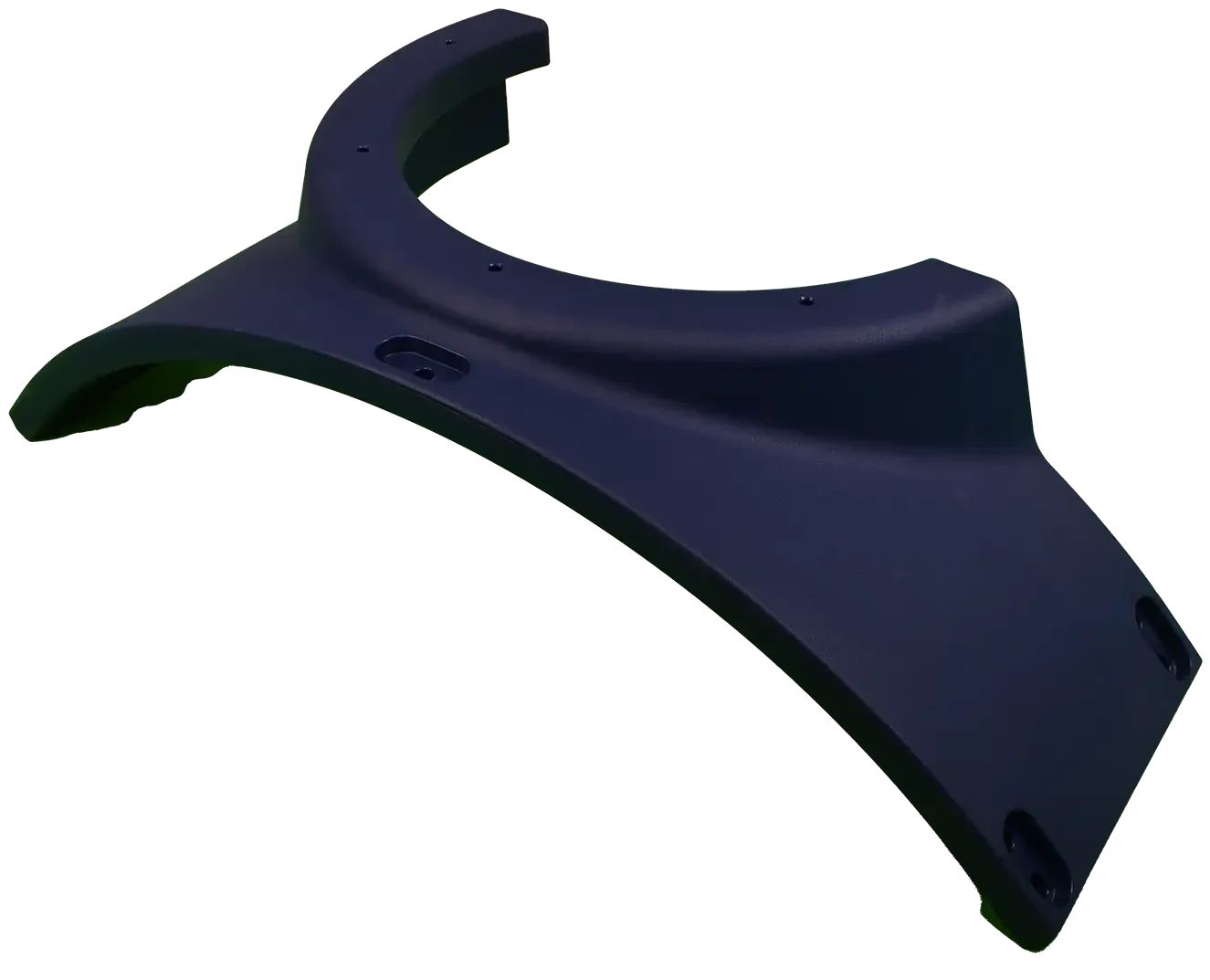

Durable rotomoulded loader parts

Rotomoulded plastic products are made by heating plastic pellets in a mould and rotating the mould in all directions, which evenly distributes the plastic and creates a uniform product. This process results in several advantages for building and construction manufacturers of, for example, loader parts.

The process creates a product that is resistant to impact, chemicals, and extreme temperatures. This means that the fuel tanks, Adblue tanks, hydraulic oil tanks, air ducts, and mudguards made from rotomoulded plastic will have a longer lifespan, reducing the need for replacements and reducing costs.

Furthermore, loader parts are lightweight. This is particularly beneficial for manufacturers of loaders, because the weight of the machinery is an important factor in its overall efficiency and performance. Rotomoulded shovel parts, front loader parts or payloader parts are significantly lighter than metal parts, which means that the loaders will be able to operate more efficiently and will require less energy to move.

Long-lasting lifetime

High resistant materials

Easy Installation Process

Corrosion-resistant parts for loaders

Rotomoulded plastic products are resistant to corrosion. This is particularly important for fuel tanks, AdBlue tanks, and hydraulic oil tanks, because these components are exposed to potentially corrosive materials. Plastic tanks will not rust, corrode, or degrade over time, which means they will not leak or cause damage to the loaders.

Additionally, rotomoulded loader parts, such as shovel parts, front loader parts and payloader parts, can be designed and manufactured to meet specific requirements. This means that the manufacturer of the machinery can work with us to create custom-made parts that are tailored to the specific needs of their loaders. This allows the manufacturer to have complete control over the design and function of the parts, ensuring that they are optimized for their loaders.

Julia

Sales Manager

"A satisfied customer is the best business strategy of all"

your idea

to life. Start now!